Summer Construction Safety

Summer’s here, which means so is construction season. It seems that as soon as a crew finishes one job, they’re on to the next almost immediately. And all that rushing around can be the cause of cutting corners and accidents.

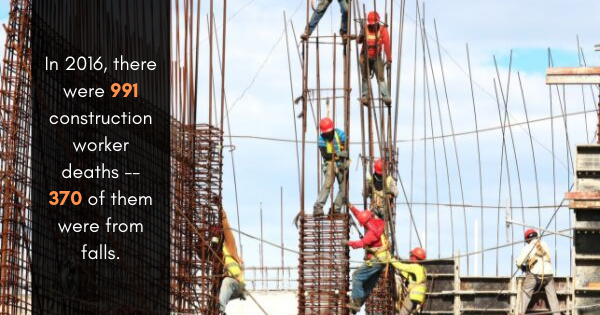

In the construction industry, falls are the number one cause of death, whether by faulty rigging, rigging that hasn’t been properly inspected, or just plain inattention. But these deaths are preventable. In fact, proper fall protection is the most frequent Occupational Safety and Health Administration (OSHA) violation.

In 2016, there were 991 construction worker deaths — 370 of them were from falls. Most of the workers either weren’t wearing fall protection or weren’t wearing it properly. According to the OSHA, employers need to plan, provide, and train.

A job should be planned out thoroughly to prevent accidents. This means employers not only need to plan ahead and provide all the necessary safety equipment, but they also need to budget for it.

Employers also need to provide fall protection equipment, such as scaffolding, ladders, lifting slings, railings, cable hardware, personal fall arrest systems, or harnesses.

All employees should be trained to use their safety equipment. This includes how to set up and use the equipment.

Ask any rigging supply company why falls are so common in the construction industry and they will tell you that workers do a good job of preparing their rigging for a new job site, but everything seems to get thrown into a box haphazardly once the job is done.

To prevent accidents and to abide by OSHA regulations, a rigging supply company will suggest that you inspect your equipment before it’s sent to the next job site. You should organize, take inventory, and inspect everything beforehand.

A rigging supply company will also tell you that this rarely happens. Another option is to inspect everything on-site when it arrives. But that can be a challenge when everything was packed quickly, in poor condition, or without documentation from the last site.

One option when this happens is to hire a rigging inspector. An inspector can come to your site, shop, or yard. They can then inspect your cable and rigging supplies for you.

A third-party inspector can even help you set up systems for keeping your rigging in order. Have a box specifically for broken equipment and one that holds replacement parts. This can help keep everything organized and ensure that broken equipment isn’t sent to a new job site.